|

|

|

6504 NW. 77th Court. Miami,

Florida 33166

USA • Phone: 305-556-6251

Fax: 305-556-6256

sales@ac1supply.com |

|

|

| |

|

|

Curtain Wall Framing

Structural Studs

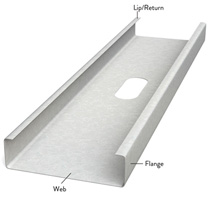

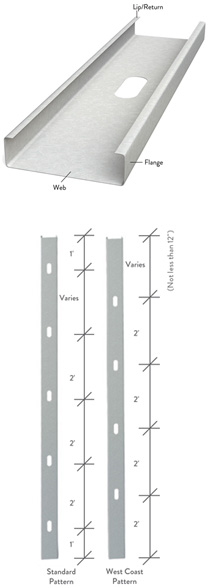

ClarkDietrich Cold-Formed Steel C-Studs

ClarkDietrich studs are made in a variety of flange widths to meet different

applications.

• Standard Web Size: 2-1/2”, 3-1/2”, 3-5/8”, 4”, 5-1/2”, 6”, 8”, 10”, 12”, 14”

• Flange Sizes: 1-3/8”, 1-5/8”, 2”, 2-1/2”, 3”.

• Thickness: 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils

(12ga).

• 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel.

• 54mil (16ga), 68mil (14ga) and 97mil (12ga) products are produced with 50ksi steel

unless otherwise noted.

• Standard coating: CP60 (G90 available)

• Additional member depths of 7-1/4", 9-1/4", 11-1/2", 13-1/2" and 14" are also available.

•All studs are color coded for easy identification.

ClarkDietrich S137 (CWN) member have a 1-3/8" flange and 3/8" return and are used

to support the exterior skin or cladding material (metal, stone, tile, glass, etc.) and the

wind loads to which they are subjected.

ClarkDietrich S162 (CSJ) members have a 1-5/8" flange and a 1/2" return and are

considered the industry standard. S162 members are preferred for most curtain wall

applications. They also provide the vertical strength necessary for demanding load-bearing

structural applications and sufficient strength for many joist applications.

ClarkDietrich S200 (CSW) members a 2" wide flange and a 5/8" return that provides a

larger bearing surface for attaching sub-flooring or sheathing materials. This framing

member is also used in axial load-bearing wall assemblies.

ClarkDietrich S250 (CSE) members have a 2-1/2" wide flange and a 5/8" return and are

used in floor joist assemblies and heavy loading conditions.

ClarkDietrich S300 (CSS) members have a 3" flange and a 5/8" return and are used in

very heavy loading and long spanning conditions.

|

|

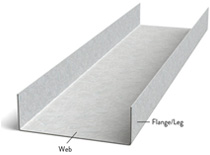

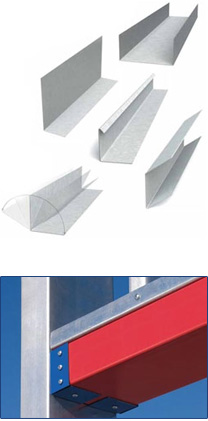

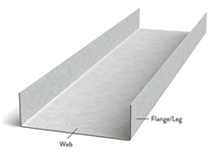

Structural Track

ClarkDietrich Cold-Formed Steel Track

U-shaped channel runners used as the top and bottom tracks to secure wall studs or end

support closures for floor joist framing.

• Standard Web Size: 2-1/2”, 3-1/2”, 3-5/8”, 4”, 5-1/2”, 6”, 8”, 10”, 12”, 14”

• Leg heights: 1”, 1-1/4”, 1-1/2”, 2” and 3”.

• Thickness: 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils

(12ga).

• 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel.

• 54mil (16ga), 68mil (14ga) and 97mil (12ga) products are produced with 50ksi steel

unless otherwise noted.

• Standard coating: CP60 (G90 available)

• Standard 10’ lengths. (Custom lengths available)

• Additional member depths of 7-1/4", 9-1/4", 11-1/2", 13-1/2" and 14" are also available.

• All track are color coded for easy identification.

ClarkDietrich structural track is a U-shaped framing component used as top and bottom

runners to secure wall studs. Structural track is also used as end support closures for

joists at exterior or foundation walls, head and sill plates of wall openings and solid

blocking. Track is normally ordered in corresponding size and gauge to the wall studs.

Longer leg track is used for deflection conditions or to accommodate uneven or

inconsistent floor or ceiling conditions. Slip track for track-over-track assemblies is also

available.

|

|

Corner Angle

Heavy-gauge utility or corner angle

Heavy-gauge corner angle is commonly used for a variety of applications including:

concrete pour stop, connection strut or angle, roof ridge angles and corner reinforcement.

• Standard leg sizes are 2”x2” and 3”x3”.

• Wider and uneven leg sizes available.

• Available in 18, 16, 14 and 12 gauge.

• Standard 10’ lengths. Other lengths available on request.

|

|

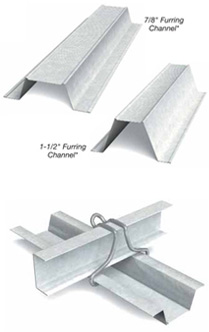

Furring Channel for Walls and Ceilings

Economical hat-shaped framing component used to “furr” out ceilings and

masonry walls.

• Provides noncombustible furring for interior and exterior walls

• Use to level uneven surfaces

• Available in 7/8” and 1-1/2” depths in 25, 20, 18 and 16 gauge

• Standard lengths are 10’ and 12’. Other lengths available

• Hemmed leg furring channel (as shown) is only available in 25 gauge

ClarkDietrich furring channel is a hat-shaped corrosion-resistant framing component used

to furr out masonry walls and ceiling assemblies. In concrete wall applications, furring

channel is installed vertically to the wall surface using concrete nails or power-driven

fasteners. Gypsum panels are then screw-attached to the furring channels. In drop ceiling

applications, furring channels can be attached directly to the underside of the building

structure using Metal Furring Channel Clips, tie wire, screws or power-driven fasteners.

Heavier gauge furring enables greater spans and loading capacity. 18- or 16- gauge

furring is commonly used for purlins in exterior applications. |

|

Custom Shapes

Custom fabricated shapes, clips, bends, continuous angles, long leg tracks and

miscellaneous closures

ClarkDietrich custom fabricates just about any shape, bend, angle or specialty framing

component to your exact specification. Custom parts include corner angles, roof ridge

angles, clip angles, long and uneven leg tracks, eave closures, support clips and furring

channels. To ensure proper fabrication, Dietrich requires a detailed, fully dimensioned

part drawing at time of order placement.

• Precision fabrication meeting exacting specifications.

• Wide array of custom options.

• Fully dimensioned part drawings must be provided.

|

|

| |

Door + Window Framing Systems

RedHeader RO™ Rough Opening System

Labor Saving System for Exterior Curtain Wall Openings & Interior Non-Load

Bearing Openings

ClarkDietrich Building Systems is proud to bring you this innovative labor saving system

that reduces the number of framing components required to frame a rough opening and

significantly reduces the onsite labor to assemble multiple window or door structure.

Up to 50%!

What is RedHeader RO™

• Framing around a NON-LOAD BEARING Door or Window using single members in lieu

of a built-up header or jamb system.

• Can be used for Exterior or Interior Framing.

• Header & Jamb system has: ◦Extra wide Flanges (3” and 3-1/2”)

• The Drop’N Lock™ Clip is flush with jamb for a smooth drywall finish.

• System SAVES LABOR in Installation and Handling!

Save Labor on Multiple Openings

• No More Built-Up Jambs.

• Replace Lay-in & Boxed Headers.

• Adjustable Drop’N Lock™ Clip.

• Flat Surface for Drywall Finish.

• Reduces Material Pieces, Weight and Screws.

• Insulation Installs Quicker.

• Headers are Pre-Cut to Length and Marked RED to Identify Easily.

• SAVES LABOR – In Installation and Handling.

|

HDS® Framing System

The Heavy-Duty Stud (HDS®) Framing System

The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective,

multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss

chords and webs. The superior strength and carrying capacity of the HDS means higher

performance with fewer members. It means eliminating box beam headers, nesting track

and stud for posts and jambs and eliminating multi-member, built-up truss chords and

webs. It also means improved finish quality by eliminating excessive material and screw

head buildup around doors and windows.

Applications

•Curtain-wall headers, jambs and sills

•Drywall headers and jambs

•Load-bearing jambs

•Trusses

•Shearwall posts

•Heavily loaded or long-span wall studs

•Any other application involving nested stud and track

Benefits

•Outstanding bending strength in two directions

•Reduces installation time by 50%

•Eliminates box beam header assembly

•Reduces material and labor costs up to 50%

•HDS® can be screw-attached from either side

•Eliminates stud-to-track nesting for post, header and jamb studs

•Openings up to 15' wide

•Eliminates multimember built-up truss chords and webs

•Eliminates excessive bridging for load-bearing walls and posts

•Improves drywall finishing around doors and windows without screw head buildup

•Superior axial strength

|

|

ProX Header® System

Brady’s ProX Header system has revolutionized how door & window openings

are framed.

The ProX is ideal for all types of door, window, shaftwall, HVAC, and ventilation openings.

This simple system has application to a wide range of openings and can carry greater

loads with less steel. The contractor community prefers the ProX system over traditional

built-up headers.

Applications / Benefits

The Brady ProX Header system provides a direct solution to the many problems

associated with traditional headers that have troubled architects, engineers, contractors

and inspectors for decades. ProX Header is a superior and cost effective alternative

to the limited span capabilities of a single track and the excessive build-up of traditional

box headers. The ProX Header is designed for all interior and exterior door and window

wall openings in the 3 to 12 foot wide range.

• ProX Header offers a standard single piece design

• ProX installs flush leaving a smooth finish

• ProX installs quickly and consistently

• ProX saves time and money

L-Header

Preformed L-header that slides into place quickly

L-Headers are prefabricated light-gauge 90° L-sections that are used in load-bearing wall

framing. L-headers slide easily into place and eliminate the labor-intensive process of

built-up field-assembled headers. L-headers may not work in all loading situations.

Proper loading comparisons should be examined, especially when considering uplift loads.

L-headers may be installed as single, one header one side, or double, two headers, one

on both sides.

• Substantial labor savings.

• Lightweight and easy to handle.

• Available in stock and custom lengths.

|

|

TradeReady® Header

Preformed U-shaped header that slides easily over wall assembly and provides

maximum carrying capacity

The TradeReady® load-bearing one-piece header drastically reduces labor costs when

compared to standard box beam headers constructed with C-shaped members.

TradeReady® headers are pre-engineered to fit standard door and window openings.

Just slip the TradeReady® header over the top track, screw to the jamb studs and your

header is complete. These headers have great load-distribution qualities and enable

access for insulation after the framing is completed.

U.S. Patent No. 5,689,922 and other foreign patents.

• Huge labor savings.

• Easy and fast installation.

• Pre-engineered for most door or window openings.

• Easily insulated after installation.

|

|

Head-of-Wall Deflection Systems

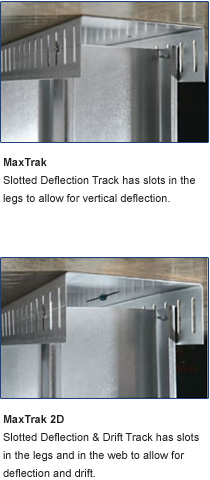

MaxTrak® Slotted Deflection Track

Performance that stands up to deflection.

For superior head-of-wall vertical deflection, and the added benefit of horizontal drift

movement, ClarkDietrich introduces two solutions—MaxTrak™ Slotted Deflection Track

and MaxTrak™ 2D Slotted Deflection & Drift Track. The MaxTrak System allows the top

of the wall stud to float within the track legs. This connection allows for vertical live load

movement of the primary structure without transferring axial loads to the wall studs.

In addition, MaxTrak 2D also has slots in the web to allow for horizontal drift when

seismic designs are required.

Construction Advantages:

• Provides positive attachment to wall framing for overall wall strength with no additional

components

• Total allowable vertical (deflection) movement of 1-1/2" (3/4"±)

• Total allowable horizontal (drift) movement of 4" (2"±) (MaxTrak 2D only)

• One-piece system reduces the cost of materials and labor

• Easy installation reduces labor costs

• Fire-rated system integrates with a variety of UL® head-of-wall fire stop systems

• MaxTrak meets IAPMO #0145 Evaluation Report

• Can be used for both interior non-load bearing walls and exterior curtain wall systems

• Guideline at center of vertical deflection slot helps installers correctly position fasteners

accurately and quickly

Design Advantages:

ClarkDietrich Engineering Service & Technical Services are Here to Support You

• MakTrax and MaxTrak 2D is IAPMO tested for lateral and horizontal loads.

• Use our MaxTrak Selection Guide for quick preliminary sizing from ClarkWestern’s

technical department allowing you to see the advantages of using the MaxTrak system

compared to the conventional systems.

|

|

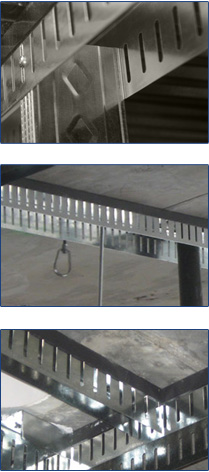

SLP-TRK® Slotted Deflection Track

Most cost-effective, positively attached fire-rated deflection system

It’s a real challenge these days meeting head-of-wall codes for fire stop and life safety

issues while maintaining the ability to absorb vertical movement in low-, mid- and highrise

buildings. Brady's SLP-TRK* slotted track is the solution.

Brady's SLP-TRK® slotted track provides a positive attachment for overall strength and

allows for vertical movement caused by normal head-of-wall and floor extension or

compression. SLP-TRK® slotted track smoothly integrates with a variety of wall

installation systems and is extremely user-friendly as well as economical. The simple

design and easy installation reduces the cost of materials and labor. And the installer can

use the head-of-wall systems he prefers to work with.

SLP-TRK® slotted track systems comply with the toughest code requirements in

North America, if not the world. It has been tested with a variety of leading fire-stop

products and has outperformed the requirements of stringent fire and hose stream

testing of ASTM E 119 and ASTM E 814. SLP-TRK has also met and exceeded the latest

seismic cycling standards found in UL2079 and ASTM E 1966.

The SLP-TRK® slotted track has achieved the following building code approvals:

• UL Classified R19236

• UL Certified for Canada XHL17

• LA City RR25344

• OSHPD R#0371

• NY City MEA 285-01-M

SLP-TRK® slotted track is installed directly to the slab or corrugated metal roof deck

using #10 sheet metal screws, Tapcon** concrete screws or power-driven fasteners.

Fasteners must be placed at 8" or 12" intervals depending on the flute intervals of the

metal decking material. Studs must be cut 3/4" shorter than floor-to-ceiling height to

allow for ceiling deflection. Studs are attached to the track through the midpoint of flange

slots using #8 self-tapping wafer-head screws on each side of the stud.

U.S. Patent # RE 39,462

• Positive attachment that allows up to 1” of vertical movement.

• UL*** approved 1- and 2-hour systems.

• Meets IBC, BOCA, SBCCI, ASTM, UL2079, and UBC building codes and standards.

• Single track assembly.

|

|

Deep Leg Deflection Track System

Traditional, single-track deflection assembly for curtain-wall framing

This traditional assembly accommodates the deflection of floor beams or floor decks

at the head of wall. The single long leg track assembly requires 1-1/2" cold-rolled

channel and 1-1/2" x 1-1/2" 16-gauge EasyClip™ Clip Angles (U-Series™) installed

continuously throughout the uppermost punch-outs to align the studs vertically within

the plane of the wall. Deflection track details must be designed for the specific conditions

of a building to accommodate the required deflection and end reactions of the studs.

Deflection tracks cannot be used in axial load-bearing stud conditions or above

continuous window spandrels.

• Nonproprietary system.

• Traditional framing components.

• Requires U-Channel and clip angles

.

DoubleTrack™ System

DoubleTrack™ or track-over-track curtain-wall deflection system

A DoubleTrack™ system is a two-piece assembly that accommodates deflection of

exterior curtain walls. A custom-made deep leg outer track is installed to the underside

of the floor deck. A wall assembly is constructed on the floor and slid into place.

The wall assembly is built to allow a “gap” at the top for deflection.

The track-over-track assembly, although still used, is becoming less and less common.

The development of innovative deflection systems like the MaxTrak® or SLP-TRK®

Slotted Deflection System has significantly improved and streamlined the assembly

process. DoubleTrack™ deflection assemblies cannot be used in axial load-bearing

stud conditions or above continuous window spandrels.

• Eliminates bridging.

• Requires custom top track and longer lead times.

|

|

BlazeFrame® Fire Stop Deflection Track

fire stop Deflection Track Products

BlazeFrame is an innovative steel framing, fire stop system. An intumescent strip

affixed to steel profiles simultaneously frames, fire stops, and sound seals both dynamic

and static joints.

The cured intumescent is odor free, effective immediately, and remains unaffected by

freezing, wet or humid conditions. BlazeFrame offers protection and support of wall

framing materials for up to 3 inches of movement capability. Designs utilizing

BlazeFrame assemblies eliminate caulks, sprays, drywall rips, and contour drywall

‘castle’ cuts throughout the joint systems. Our UL (Underwriters Laboratories) classified

joint systems provide for positive attachment of wall framing, 100% unencumbered

movement, smaller installed joints, and sound control with no fatigue or degradation.

BlazeFrame Advantages:

• UL Classified and Listed Joint Systems

• Shaft, Single, and Chase Walls

• 2 1/2” - 8” Wall Framing

• Dynamic and Static Joint Protection up to 3”

• Up to 3 Hour Ratings

• Lowest Achievable L-Rating

(air/smoke leakage)

• UL 2079 Level II and Level III Cyclical Certi�fication

• No Fatigue to Joint or Substrate Materials

• Smaller Installed Joints

• Reduced Sound Transmission |

|

Fast Top™ Clip (FTC3, FTC5)

Used in head-of-wall deflection conditions for exterior curtain wall and interior,

nonload-bearing walls

ClarkDietrich Fast Top™ Clips are used in head-of-wall deflection conditions for in-fill

curtain-wall assemblies to provide for vertical movement. These clips are used in place

of or in combination with deflection track. They provide a positive attachment and do not

require bridging installed continuously throughout the upper most punchouts.

The Fast Top™ clip can be attached to the underside of structural members, concrete

decks or floor assemblies. Studs must be cut less than full height to enable vertical

movement up to 2-1/2" (1-1/4" up and down). Fast Top™ Clips install quickly with welds,

screws, or powder actuated fasteners. FastClip™ deflection screws are used to attach

the clip to the cold-formed framing and to ensure frictionless deflection. These clips are

also embossed with fastening patterns to ensure accurate placement of fasteners.

• Vertical movement up to 2-1/2" (1-1/4" up and 1-1/4" down).

• Available in 3-1/4” and 4-3/4” widths.

• FastClip™ Deflection Screws (included) provide frictionless slip connection.

• U.S. Patent No. 6,688,069 |

|

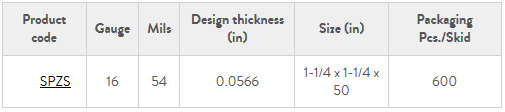

Bridging + Bracing

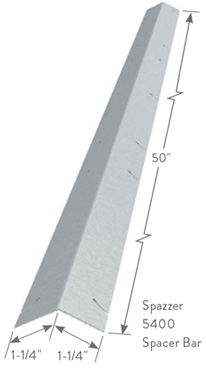

Spazzer® 5400 Bridging Bar

Facilitates the rapid erection of structural wall framing

ClarkDietrich TradeReady® Spazzer® 5400 spacer bar is a pre-notched, 16-gauge,

galvanized steel spacer and bridging bar, engineered to facilitate the rapid, efficient

erection of exterior curtain wall framing, loadbearing walls and high interior partitions

constructed of structural studs. Until now, most bridging in steel studs was accomplished

with cold-rolled channel that required bridging clips or welding.

The Spazzer bridging bar is equipped with proprietary prepunched slots that reduce

installation costs up to 40% and provide excellent torsional and lateral stud restraint.

The Spazzer Bar Guard™ retainer clip or the Spazzer Snap-In Grommet should be used

to secure the Spazzer bar when used in load-bearing applications.

• Saves up to 40% in combined labor and material costs.

• Prenotched at 12", 16" and 24" intervals, so no layout is needed.

• Eliminates clip angles and the labor required to install them.

• U.S. Patent No. 6,708,460 and other patent pending.

|

|

U-Channel (CRC)

Traditional cold-rolled Channel (CRC) for bridging

ClarkDietrich U-Channel or Cold Rolled Channel (CRC), attached to the studs with

clipss or weld, are one of the most common bridging methods used to provide

resistance to stud rotation and minor axis bending under wind and axial loads.

1-1/2" U-Channel is passed through the stud knockout and secured with EasyClip™

(U-Series™) or SwiftClip™ (L-Series) Clip Angles and screws. Lateral bracing is typically

installed at a maximum of 48" O.C. Consult ClarkDietrich’s Technical Services for proper

spacing. Welding U-Channel to the stud is acceptable but should not be used in studs

wider than 6".

Caution:

• Clip Angles must be used with screws to brace cold-formed framing properly.

U-Channel does not provide proper bracing if it is not adequately attached to the framing

member.

• Extreme care should be taken in the quality of the weld. If the weld burns through or

does not penetrate, the U-channel will not be effective.

|

|

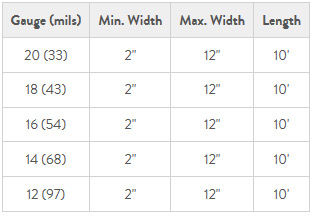

Blocking / Strapping

Commonly used bracing for wall studs deeper than 6"

Properly spaced horizontal steel bracing provides resistance to stud rotation and minor

axis buckling under wind and axial loads. Block and strapping is typically used when wall

studs exceed 6". U-Channel or the Spazzer® bar does not provide sufficient bracing for

members wider than 6". Both stud flanges must be attached to top and bottom runner

flanges to provide proper end support. Floor and ceiling runners must also be anchored

securely to the structure. To utilize the stud’s load carrying capacity fully, horizontal

bracing must be installed at proper intervals.

Lateral bracing consists of a field-cut stud or track for solid blocking and steel strap

bracing on both flanges of the studs. Solid blocking is placed at each end of the wall,

adjacent to wall openings and 8' O.C. maximum. The blocking is attached to each

adjacent stud via EasyClip™ E- or S- Series™ clips, or when a track is used, the flanges

are cut, the web bent and a minimum 4" overlap is used to secure the track block to the

studs. Strap bracing, 2" wide and 20-gauge (33 mil) minimum, is fastened to each solid

block and stud flange.

• Blocking is field cut.

• Used if knockouts do not align.

|

|

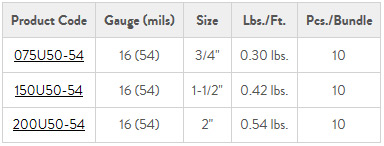

Tension Strapping / Shear Wall Bracing

Bracing for load-bearing framing to resist racking under wind and seismic loads

Diagonal tension strapping and gusset plate components are used in combination to

provide shearwall (racking restraint) for light-gauge load- bearing framing under wind and

seismic loads. They are normally installed on both sides of the wall directly over framing

members and are easily covered with facing materials. Straps are positioned diagonally

from the bottom track to the top track. In order to resist load in each direction, an

X-configuration should be used. At a minimum, double studs are positioned at ends of

the X-brace to serve as compression studs.

Straps are either attached directly to the compression studs or are attached via Gusset

Plates. Compression studs must be anchored to the foundation, normally with Simpson*

uplift anchors. For multi-story construction, the uplift loads are extremely high. It is not

uncommon to require 20,000 to 40,000 pounds of uplift force at these connections.

Since Simpson® anchors are not designed to resist this magnitude of force, it is

recommended that embedded plates be installed prior to pouring the concrete foundation.

A heavy steel assembly is then welded to the embedded plate and to the compression

studs.

Caution: Racking loads are first transferred to the roof or floor decking and then to the

shearwalls (X-bracing). The X-bracing then relies on a proper foundation to resist uplift

and shear forces. In order for the system to function properly, the load path from the roof

or floor deck to the shearwalls to the foundation must be complete. This normally requires

additional bracing, blocking, track and rim splices, drag struts, uplift anchors and

heavy-duty foundations.

• Strapping is available in flat lengths and coil form.

• Available widths are 2”, 4”, 6”, 8”, 10” and 12”.

• Gauges: 20 (33 mils), 18 (43 mils), 16 (54 mils), 14 (68 mils) and 12 (97 mils).

• Standard gusset plate sizes are 6”x 6”, 6”x 12” and 12”x 12”.

|

|

Backing Plate

Added support where shelves, cabinets, fixtures or handrails are installed

ClarkDietrich's backing plate is a general multipurpose flat stock that is used for backer

plate to support shelves, cabinets, fixtures or handrails when applied to metal framing.

Backing plate should not be used as tension strapping or cross bracing. Diagonal

Tension Strapping should be used in those applications.

• Use as backer plates for attachment of fixtures to metal stud walls.

• Available in 2”, 3”, 4”, 6”, 8”, 10” and 12” widths and 25 and 20 gauge.

• Standard length is 10’. Other lengths and coil stock are available.

|

|

Structural Studs

ClarkDietrich Cold-Formed Steel C-Studs

ClarkDietrich studs are made in a variety of flange widths to meet different applications.

• Standard Web Size: 2-1/2”, 3-1/2”, 3-5/8”, 4”, 5-1/2”, 6”, 8”, 10”, 12”, 14”

• Flange Sizes: 1-3/8”, 1-5/8”, 2”, 2-1/2”, 3”.

• Thickness: 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils

(12ga).

• 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel.

• 54mil (16ga), 68mil (14ga) and 97mil (12ga) products are produced with 50ksi steel

unless otherwise noted.

• Standard coating: CP60 (G90 available)

• Additional member depths of 7-1/4", 9-1/4", 11-1/2", 13-1/2" and 14" are also available.

• All studs are color coded for easy identification.

ClarkDietrich S137 (CWN) member have a 1-3/8" flange and 3/8" return and are used to

support the exterior skin or cladding material (metal, stone, tile, glass, etc.) and the wind

loads to which they are subjected.

ClarkDietrich S162 (CSJ) members have a 1-5/8" flange and a 1/2" return and are

considered the industry standard. S162 members are preferred for most curtain wall

applications. They also provide the vertical strength necessary for demanding

load-bearing structural applications and sufficient strength for many joist applications.

ClarkDietrich S200 (CSW) members a 2" wide flange and a 5/8" return that provides a

larger bearing surface for attaching sub-flooring or sheathing materials. This framing

member is also used in axial load-bearing wall assemblies.

ClarkDietrich S250 (CSE) members have a 2-1/2" wide flange and a 5/8" return and are

used in floor joist assemblies and heavy loading conditions.

ClarkDietrich S300 (CSS) members have a 3" flange and a 5/8" return and are used in

very heavy loading and long spanning conditions.

|

|

Structural Track

ClarkDietrich Cold-Formed Steel Track

U-shaped channel runners used as the top and bottom tracks to secure wall studs or end

support closures for floor joist framing.

• Standard Web Size: 2-1/2”, 3-1/2”, 3-5/8”, 4”, 5-1/2”, 6”, 8”, 10”, 12”, 14”

• Leg heights: 1”, 1-1/4”, 1-1/2”, 2” and 3”.

• Thickness: 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils

(12ga).

• 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel.

• 54mil (16ga), 68mil (14ga) and 97mil (12ga) products are produced with 50ksi steel unless otherwise noted.

• Standard coating: CP60 (G90 available)

• Standard 10’ lengths. (Custom lengths available)

• Additional member depths of 7-1/4", 9-1/4", 11-1/2", 13-1/2" and 14" are also available.

• All track are color coded for easy identification.

ClarkDietrich structural track is a U-shaped framing component used as top and bottom

runners to secure wall studs. Structural track is also used as end support closures for

joists at exterior or foundation walls, head and sill plates of wall openings and solid

blocking. Track is normally ordered in corresponding size and gauge to the wall studs.

Longer leg track is used for deflection conditions or to accommodate uneven or

inconsistent floor or ceiling conditions. Slip track for track-over-track assemblies is also

available.

|

|

HDS® Framing System

The Heavy-Duty Stud (HDS®) Framing System

The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective,

multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss

chords and webs. The superior strength and carrying capacity of the HDS means higher

performance with fewer members. It means eliminating box beam headers, nesting track

and stud for posts and jambs and eliminating multi-member, built-up truss chords and

webs. It also means improved finish quality by eliminating excessive material and screw

head buildup around doors and windows.

Applications

• Curtain-wall headers, jambs and sills

• Drywall headers and jambs

• Load-bearing jambs

• Trusses

• Shearwall posts

• Heavily loaded or long-span wall studs

• Any other application involving nested stud and track

Benefits

• Outstanding bending strength in two directions

• Reduces installation time by 50%

• Eliminates box beam header assembly

• Reduces material and labor costs up to 50%

• HDS® can be screw-attached from either side

• Eliminates stud-to-track nesting for post, header and jamb studs

• Openings up to 15' wide

• Eliminates multimember built-up truss chords and webs

• Eliminates excessive bridging for load-bearing walls and posts

• Improves drywall finishing around doors and windows without screw head buildup

• Superior axial strength

(All profiles are unpunched in the East Coast). |

|

|

| |

| ©2010 AC1 SUPPLY, INC - All rights reserved | Web Design & Development by Quint Advertising, Inc |

|

|